|

|

||

|

Home |

|||

GDI Injectors - Gasoline Direct Injection  To meet Cheaper Prices, Better Performance and Greater Fuel Economy demands, the Vehicle Manufacturers are switching to Direct Fuel Injection, be it Diesel or Gasoline Fuel, Direct Injection is their only way forward.

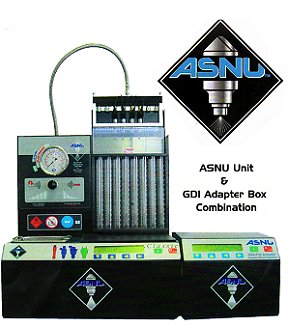

To meet Cheaper Prices, Better Performance and Greater Fuel Economy demands, the Vehicle Manufacturers are switching to Direct Fuel Injection, be it Diesel or Gasoline Fuel, Direct Injection is their only way forward.The abbreviation GDI (with a capitalised letter "I") is a registered trademark.of Mitsubishi Motors. Other companies have developed other names for what is Gasoline Direct Injection (GDI) engines but have had to change their brand name of their system, VW/Audi have branded their system (Fuel Stratified Injection) Alfa Romeo — JTS, Renault — HPI and so on, the fact is they are all Gasoline fuel fired directly into the combustion chamber. On a direct injection Engine, a very fine mist of fuel is injected directly in to the combustion chamber at a pressure of between 50 — 120 Bar, depending on the type of system. During idle and light throttle, the metered fuel is injected at microscopic milli second (mS) durations at a pressure of approximately 50 bar. This design enables the engine to operate a stratified charge combustion, described by most of the vehicle manufacturers as an Ultra Lean Burn mode, giving a much improved fuel efficiency, great engine torque and reduced Exhaust Emission levels at low load. To achieve these pressures, the gasoline is pressurized by a high-pressure pump that is a combination of mechanically driven and Electronically controlled and mounted on the engine. This pump compresses the fuel to the pressure level required in fuel rail With the sequential firing GDI systems, the injector only opens to a maximum of 5mS. As the fuel requirement increases, the injector remains at 5mS and the pump pressure increases to meet the demand, allowing the injector to open and close quickly and efficiently. No more "Duty Cycle" as we have known it. These engines use a very high specification injector, Hitachi, Bosch, Denso and Siemens being the major suppliers. The ASNU GDI Adapter Box has been designed to drive Gasoline Direct Injection (GDI) injectors with an approved supply of current and voltage to simulate injector electronic operation as on the engine. Correct Electronic Operation is critical when examining the injector's response to changes in mS & RPM. Examination of the injectors Fuel Distribution and Atomisation is equally critical to the Engine's Correct Running, Performance, Fuel Economy and Emission Outputs.  Carbon can build up on the tip of the injector and interfere with the distribution and atomisation of the fuel. Even the slightest loss of the fuel delivery will have an adverse effect on the engines Drivability, Power Output, Fuel Economy and Exhaust Emissions. This style of injector can have varying types of spray patterns, depending on the engine requirements, but all of them will be atomising a much smaller fuel droplet size. To explain the difference, a conventional injector would have a fuel droplet size, as an example, of 165 micron, some GDI injectors would produce a fuel droplet of say, only 65 micron. The ASNU GDI Adapter Box is designed to work with all currently produced injectors. To enable the user to analyze the fuel spray pattern easier and measure the fuel flow rate more accurately The GDI Adapter Box has a specific range of settings that will enable the user to check the injectors electronic operation, clearly see the injectors spray pattern form and accurately measure the injector delivery flow rates. These systems use a much smaller duration of opening time and fuel metering supply. To enable the injectors to operate and respond to these demands, they must receive a greater power supply and the injectors are of a much higher standard of those used in a conventional injection system. Even the slightest irregularity in the Fuel Spray pattern would result in illumination of the Engine Check Light, but with no specific cause identified. GDI injectors are difficult and time consuming to remove and re-fit, would you fit a set of injectors without ensuring they are working correctly? © Text courtesy ASNU UK Manufacturers preferring their own abbreviation of the system, here are some of the ones currently in use: CGI = Mercedes Benz (Charged Gasoline Injection) DISI = Ford/Mazda (Direct-Injection-Spark-Ignition) FSI = VW Audi ( Fuel Stratified Injection) GDI = Mitsubishi Peugeot Citro‰n, Hyundai, Volvo, (Gasoline Direct Injection) HPDI = Porsche (High Pressure Direct Injection) HPI = BMW (High Precision Injection) IDE = Renault (Injection Direct Essence) JTS = Alfa Romeo (Jet Thrust Stoichiometric) SCi = Ford (Smart Charge Injection) SIDI = Holden (Spark Ignition Direct Injection)   |

|

|||||||||||||||||||||||||||||||||||||

| © 2005 - 2019 Westfield Design |